Advantage:

1.Higher Speed,max 90-100m/min

2.9 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder up and down when making different diameter paper

|

Layer of paper |

3-4 layers |

PLC controller |

Schneider |

|

|

|

|

Schneider |

|

Min.straw outer diameter |

5mm |

Program version |

XJ3.0 |

|

Max. thickness |

1mm |

Servo system |

Schneider |

|

Min. thickness |

0.2mm |

Performer |

Schneider |

|

|

|

Max.length(between 2 blades) |

|

|

Straw max. Output speed |

90-100m/min |

Signal component |

Omron |

|

Winding system |

2 servo/1 pc belt |

Pneumatic component |

Airtac |

|

|

|

|

|

|

|

|

Sync tracking cutting system |

|

|

Lenght control |

encoder |

assemble |

|

|

Operator |

1 person |

Tube rack |

Have |

|

Mandrel fixing |

Screw clamp |

Belt angle adjustment |

Wheel adjustment |

|

|

|

|

|

|

|

|

|

|

|

Dimension |

|

|

|

|

Machine dimension |

4250×640×1600mm |

Lubrication |

Electric roller |

|

|

|

|

|

|

|

|

|

Automatic paper connecting holder |

|

Wheel height |

100mm |

Belt |

Piece base band |

|

Max. spin speed |

200r/min |

Total weight |

1750KGS |

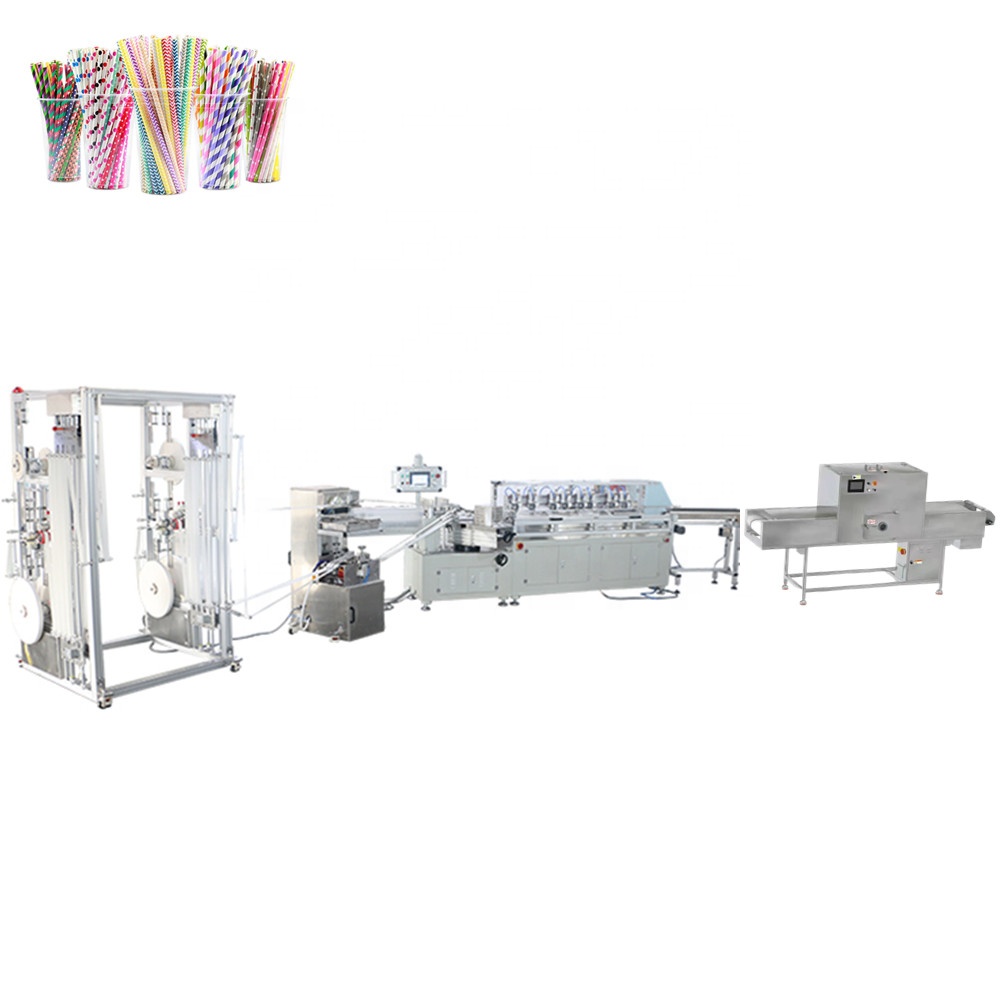

Machine with following devices

1.New improved type auto splicer (automatic paper connection device)

It is used for connection paper automatically, which can be used for 3 or 4 layer. Advantage is take less space and save labor. It is controlled by two PLC. It is more stable and faster

Specifications:

Size:1250mmx1000mmx2050mm

Paper:can be used for 3 or 4 layer paper

Speed:90-120meter/min

Weight:240kg

The air supply can connect with paper straw machine

Power supply:available for 110V-240V,50HZ-55HZ,single phase

With convenient operation and stable performance.

2. With 6kw Mircowave dryer (with hot air)

It is used for sterilization, quick drying of paper straws

Use:

This dryer is used to connect with machine, which to dry products quickly, sterilize it, and improve product safety and quality.

Control mode: PLC and HMI (touch screen) control, high degree of automation

Use environment:

1 Input power: three-phase 380V±10% (three-phase five-wire system) 50Hz±1%

2 Distribution power: ≤9KVA

3 Ambient temperature: -5~40℃, relative humidity ≤80%, no flammable and explosive gas or dust

Microwave system

1 Microwave frequency: 2450±50MHz

2 Microwave output power: 6KW (effective heating length 1.42 meters)

3 Microwave box body is made of 304 stainless steel plate

4 Microwave conveyor belt: special microwave chain plate (width 460), the angle of the guide plate at the discharge end can be adjusted, and the adjustment foot selects the enhanced type (80).

5 Speed adjustment: 0.4-4m/min continuously adjustable, using frequency conversion control technology to ensure stable and reliable speed

6 Cooling method: Magnetron air cooling.

7 Microwave leakage energy: meet the national GB10436-2008 microwave radiation safety standard (≤5mw/cm2)

8 Infrared temperature measurement, temperature measurement range, accuracy: 0-500℃, accuracy ±1℃

9 Microwave power adjustment range: 0-6KW continuously adjustable

10 Control mode: PLC and HMI (touch screen) control, high degree of automation

11 Microwave drying equipment size: 3900×640×1800mm (L*W*H)

12 Net weight of equipment: 550kgs

|

NO. |

Model no. |

Microwave Power (KW) |

Air hot power(KW) |

Capacity |

Overall size(mm) |

|

1 |

ORW6S-5G(T) |

6 |

1.5 |

50 |

3900*640*1800 |

3. Automatic glue system with auto pump, which is more convenient and clean.

We are a professional supplier mainly focused on supply paper straw machines. We supply whole production line which includes printing machine, slitting machine, paper straw making machine and straw packing machine.All of our machines have passed the European CE safety certification, with features of high safety factor, low failure rate. User-friendly. And low labor intensity. We have professional engineer support, high efficiency sales team and competitive price superiority, and attract customers from all over the world. We have exported to over 35 countries, including Portugal, Poland,Slovakia, France, Turkey, Russia, USA, Mexico, Brazil, Thailand , Indonesia,Middle east and South America countries.

We have got many good comments from our customers of machine quality and the after-sale services.

We are looking forward for more cooperation on a win-win basis!