Specification and Parameter

Adopted man-machine control interface, touch screen parameters setting, easy for operating.

Controlled by encoder, driven by servomotor. Automatic and high efficiency. Select and use famous brand suppliers for motor and electrical equipment.

Thermal/heat treatment frame to remove internal stress to keep longer service life.

Multi-control language for choosing: English, Chinese, Vietnam, Spain......

Advantage:

1.Higher Speed,max 90-100m/min

2. 9 cutting-knife system, new structure of cutting cylinder. Easier to adjust air cylinder up and down when making different diameter paper straws.

3. 5 sets servo motor for spiraling roller, cutting system moving left & right, supporting roller and cutting knifes.

4. Auto paper roll connecting function hanging bracket, auto splicer, 4 layers. Other brand paper straw making machine paper roll hanging bracket is only 3 layers.

5. Auto feeding function glue station.

6. Auto lubrication grease feeding system for cutting system.

7. Main electric parts choose famous brand, Schneider. Like main servo motor, servo motor driver, frequency converter, touch screen .

Specification and Parameter:

Model number

90-100M high speed paper straw making machine

Technical parameter

Control system

Layer of paper

3-4 layers

PLC controller

Schneider

Max. Straw outer diameter

12mm

Human machine interface

Schneider

Min.straw outer diameter

5mm

Program version

XJ3.0

Max. thickness

1mm

Servo system

Schneider

3kw*1 set

1kw* 2 sets

0.4kw *2 sets

Min. thickness

0.2mm

Performer

Schneider

Min. length

90mm

Max.length(between 2 blades)

1580mm

Straw max. Output speed

90-100m/min

Signal component

Omron

Winding system

2 servo/1 pc belt

Pneumatic component

Airtac

Cutting way

9 knives pneumatic/1 servo

synchronous control

Synchronous belt

Glue method

Double side/single side

Sync tracking cutting system

Servo sync tracking system

Lenght control

encoder

assemble

Operator

1 person

Tube rack

Have

Mandrel fixing

Screw clamp

Belt angle adjustment

Wheel adjustment

Speed control

servo

Belt tension adjustment

Wheel adjustment

Power input

3P/380V/50HZ

Paper-break stop function

have

Dimension

Glue method

Schutze glue spray system

Machine dimension

4250×640×1600mm

Lubrication

Electric roller

Floor area

9500×3500×1900mm

Paper tension control

Continuous tension control

Wheel diameter

195mm

Paper holder

Automatic paper connecting holder

Wheel height

100mm

Belt

Piece base band

Max. spin speed

200r/min

Total weight

1350KGS

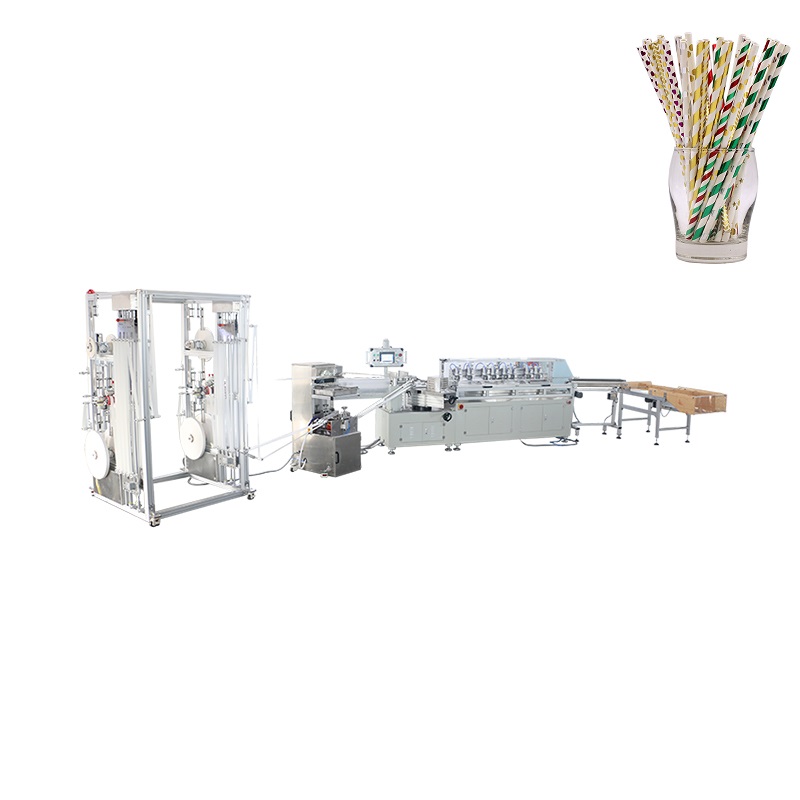

3-4 layer paper auto splicer, auto glue device, winding and control device, 9 cutting knives device, conveyor belt, paper straw collectors.

Factory